Navigating the Direct Current Revolution

Strategic Insights for Electrical Professionals in Building Systems

By Robert Kroon

Executive Summary

The global electrical landscape is experiencing a significant transformation, highlighted by the rising importance of direct current (DC) power in building systems.

This report offers a detailed analysis for electrical engineers, contractors, and systems designers. It examines the strategic value of specialized DC testing facilities, the changing dynamics of outsourcing in low-voltage and DC work, the urgent need to adopt DC power, and the essential role of integrated testing throughout the project lifecycle.

Key findings indicate that facilities like the DC Systems’ Experience Center are invaluable for de-risking innovation and fostering collaboration in this nascent field. While outsourcing remains prevalent for capacity management, a discernible shift toward insourcing core DC competencies is emerging, driven by the need for quality control and intellectual property protection amid industry skill gaps. DC power is increasingly essential for energy efficiency, renewable integration, and smart building functionality, despite existing challenges in standardization and workforce knowledge.

The report emphasizes that robust, iterative testing and commissioning protocols are paramount for ensuring safe, compliant, and high-performing DC installations. Ultimately, proactive investment in DC expertise, strategic engagement with evolving standards, and rigorous process implementation are vital for electrical professionals to thrive in this rapidly changing environment.

Introduction: The Evolving Electrical Landscape and the Rise of DC Power

The traditional alternating current (AC) dominated electrical infrastructure is undergoing a significant transformation, with direct current (DC) rapidly gaining prominence. This shift is largely driven by the increasing global demand for energy and the escalating challenges associated with grid overload and congestion inherent in traditional AC systems.[1]

The current AC infrastructure, though once reliable, is increasingly misaligned with the power needs of modern and future devices, as well as new energy generation methods. This misalignment signifies a fundamental and systemic inefficiency in the way power is distributed and consumed today. For electrical firms, continued exclusive reliance on traditional AC systems will increasingly lead to less efficient operations and potentially higher long-term operational costs for their clients, making them less competitive. This understanding provides a compelling business case for investing in DC expertise and solutions, moving beyond mere technological adoption to a strategic imperative for optimizing energy use and sustainability.

A growing number of modern electrical devices and renewable energy sources are inherently DC-native. This includes critical components like solar panels, various energy storage systems (batteries), highly efficient LED lighting, common consumer electronics such as smartphones and laptops, electric vehicles (EVs), and the proliferation of sensors and devices integral to smart building technologies.[1] The conventional AC-powered infrastructure necessitates multiple energy conversions (AC-to-DC and often back again) to power these DC-native devices. These conversion stages are inherently inefficient, leading to measurable energy losses.[2] By eliminating these unnecessary conversions, DC systems can yield substantial energy savings, with estimates suggesting a 10-20% reduction in overall electricity consumption and potentially up to a 40% decrease in grid-sourced power for commercial buildings.[2]

The transition to DC power extends far beyond the confines of individual building efficiency; it is a critical and foundational component of broader national and global energy transition and decarbonization efforts. The direct current approach can significantly relieve pressure on the power grid and help solve growing energy shortages.[1] Reduced reliance on the centralized grid strengthens energy resilience and decreases vulnerability to price fluctuations, while lower energy consumption directly correlates with a smaller carbon footprint.[2 ]

DC's seamless integration with renewable energy sources further contributes to sustainability goals.[5] For electrical professionals, this means that projects incorporating DC power are increasingly aligned with significant governmental and societal objectives related to sustainability, climate change mitigation, and energy security. This alignment can potentially unlock new avenues for funding, favorable regulatory frameworks, and a growing market demand driven by environmental and resilience mandates, rather than solely by traditional cost-benefit analyses. This elevates the importance of DC expertise from a specialized technical niche to a strategic capability that positions firms at the forefront of the evolving energy landscape.

This report is designed to equip electrical engineers, contractors, and system designers with a strategic framework for navigating the burgeoning DC revolution. It will systematically address the practical value of specialized DC testing centers, analyze current and future trends in outsourcing low-voltage and DC electrical work, articulate the strategic imperative of embracing DC power, and delineate the crucial role of DC component testing throughout the building electrical system design and implementation process.

The Strategic Value of DC Systems Experience Centers

The Direct Current Experience Center (DCS EC) in Aalsmeer, the Netherlands, is a groundbreaking facility specifically designed to demonstrate the practical advantages of DC technology within a hybrid AC/DC operational environment.[7] This center provides tangible demonstrations of various DC applications, including optimized electric vehicle (EV) charging setups, advanced office power configurations, and diverse industrial uses.

Visitors can observe how DC technology enhances processes, such as making EV charging faster and more efficient compared to traditional AC systems. Beyond demonstrations, the center serves as a vital hub for collaboration and innovation, actively uniting businesses, researchers, and policymakers who share an interest in exploring and advancing direct current technology.[7]

A key feature of the DCS EC is its live lab for testing and prototype development in a real environment. This unique setup offers an interoperable platform where industry partners can showcase their products and solutions, gaining valuable visibility and critical feedback from a wide spectrum of experts.[7] Overall, the center's mission is to elevate awareness of DC solutions, highlight technological advancements, and actively support the widespread adoption of DC technology to accelerate the broader energy transition.[1]

For electrical engineers, contractors, and systems designers, these experience centers transcend mere educational facilities; they are strategic assets that enable more rapid innovation, allow for the validation of new solutions with significantly reduced risk, and provide a tangible competitive advantage in a nascent yet rapidly expanding market. The ability to test and validate new concepts before their full-scale deployment in actual projects inherently reduces the significant financial, technical, and reputational risks typically associated with implementing novel, unproven technologies. By offering a shared, controlled, and collaborative environment, such centers effectively lower the barrier to entry for electrical firms and professionals who wish to experiment with and integrate DC solutions. This directly translates into practical business benefits such as faster time-to-market for new DC offerings, reduced project liabilities, and enhanced client confidence in adopting cutting-edge solutions.

Professionals can explore practical applications such as optimized EV charging, advanced office setups, and various industrial applications that leverage regenerative power and enhance operational performance.[7] This hands-on exposure is crucial for understanding the breadth of potential project types and identifying new business opportunities in the DC domain. The center actively fosters the exchange of critical knowledge and best practices among a diverse array of stakeholders, effectively bridging the gap between theoretical research and practical application.[7]

This collaborative environment is particularly vital for an emerging field like DC power, where industry standards and optimal practices are still evolving. It also serves as a platform for gaining significant visibility and receiving valuable feedback from a broad range of experts, which can be indispensable for firms developing new DC solutions or seeking strategic partnerships.[7]

Beyond facilitating individual concept testing, the collaborative environment and the showcasing of diverse products at the DC Systems Experience Center can implicitly or explicitly contribute to the organic development and eventual formalization of industry standards and best practices for DC systems. The center provides a unique interoperable platform where industry partners can showcase their products and solutions, and DC Systems is working with the Current/OS Foundation to help transition to more sustainable energy solutions.[7]

This collective activity and shared learning within such a hub inherently contribute to overcoming the standardization gap, as DC power systems currently lack the broad standardization and acceptance of AC technologies, even in areas as fundamental as voltage levels.[4] For electrical firms, active participation or even close observation of activities at such centers can provide invaluable early insight into emerging standards and interoperability requirements. This foresight allows them to ensure their designs, products, and installations are future-compatible and interoperable, thereby minimizing long-term technical debt and preventing market fragmentation. This proactive alignment with evolving standards represents a crucial strategic advantage in a rapidly transforming electrical landscape.

Outsourcing Dynamics in Low-Voltage and DC Electrical Work

Outsourcing has become a defining feature of many economies over the past 20 years, extending across both high- and low-paying jobs, and encompassing both support functions and core business activities.[8] Specialized staffing firms, such as Outsource.net, actively provide skilled electricians and low-voltage installers on a nationwide basis, indicating a robust and active market for outsourced labor within these electrical fields.[9] These firms support a wide array of industries, including structured cabling, fire alarm systems, security installations, audio-visual systems, industrial controls, data centers, and network/VOIP infrastructure.[9]

When implemented judiciously, outsourcing can significantly enhance operational efficiency, reduce costs, and contribute to higher revenue.[12] Outsourcing specific or partial projects offers a flexible mechanism to absorb peak workloads and manage fluctuating demands without increasing permanent headcount.[12] Firms can gain immediate access to specialized knowledge and expertise that may not be available in-house or would be costly and time-consuming to develop internally.[12]

This is particularly advantageous for niche or rapidly evolving areas like DC power, where specialized skills are scarce. In outsourced projects, the external service provider typically assumes liability for design errors, thereby mitigating the client's direct risk and potential financial exposure.[12] While the upfront fees for specialist outsourced work might appear higher, companies can realize overall cost savings by avoiding expenses associated with training in-house teams, purchasing specialized equipment, and managing employee benefits.[13]

The decision to outsource or insource DC-related work is far more complex than a simple short-term cost-benefit analysis. It represents a fundamental strategic choice about a firm's future market positioning and competitive advantage. While outsourcing might offer a quick entry point into new DC capabilities and help manage immediate project demands, a deliberate insourcing strategy for DC design and specialized engineering functions will cultivate deep internal expertise.

This internal knowledge base can become a significant and sustainable competitive differentiator as DC power becomes more widespread and integrated into mainstream building systems. This suggests an emerging trend where firms are selectively insourcing critical DC competencies while potentially continuing to outsource more routine installation or non-core support functions.

The continued and even increasing prevalence of outsourcing in the electrical sector, particularly for specialized low-voltage and emerging DC work, may not be solely a strategic cost-saving measure. Instead, it could be a significant symptom of a deeper, industry-wide skill deficit and an aging workforce that is struggling to acquire and retain the necessary expertise in rapidly advancing technologies such as DC power systems and smart grid solutions. The escalating demand for electricity driven by the proliferation of EVs and data centers, further exacerbates these workforce strains.[14]

This implies that electrical firms must proactively address these systemic talent development challenges. This can be achieved either through a deliberate strategy of strategic insourcing coupled with robust internal training programs or by meticulously managing outsourcing partnerships to ensure effective knowledge transfer and quality control, rather than simply offloading complex tasks without long-term strategic consideration. The trend to reduce outsourcing can be interpreted as a necessary, proactive response to these underlying workforce and knowledge retention challenges in a technologically dynamic and evolving industry.

Comparison of Insourcing vs. Outsourcing for Low-Voltage/DC Electrical Work

Insourcing typically offers greater quality control, enabling companies to fine-tune practices and make real-time adjustments. Conversely, outsourcing might lead to project restarts if the delivered work fails to meet stringent quality standards. Keeping work in-house offers greater command over employees and resources, thereby minimizing the risks of intellectual property leakage or unauthorized sharing. Outsourcing inherently extends the communication chain, which can increase the likelihood of misunderstandings, lead to inefficiencies, and incur wasted time and money.[13]

Companies also face an inherent risk of relinquishing control and potentially losing valuable internal expertise when tasks are outsourced. It is generally advised that tasks directly contributing to core revenue and critical to the company's resilience should remain in-house. For tasks that are highly complex, non-routine, or require extensive oversight, the administrative burden of managing external partners can be substantial, potentially transforming outsourcing into an "efficiency trap". If specialized knowledge is anticipated to be a recurring need, a long-term strategic approach involves training internal employees instead of consistently relying on external expertise.[12]

However, outsourcing remains practical for non-core business tasks, such as the digitization of paper plans, conversion of E-CAD formats, or creation of digital twins, as these can be efficiently outsourced without compromising core operations. Tasks that recur consistently and predictably are often well-suited for outsourcing to specialized partners, as this allows for streamlined processes and economies of scale.12 Outsourcing partial projects remains an effective strategy for managing and absorbing temporary surges in workload, providing flexibility without the commitment of permanent hiring.[12]

The Growing Importance of DC Power in Building Electrical Systems

DC power is rapidly becoming an indispensable component for future-proof building designs, driven by several compelling advantages. Electrical power systems utilizing DC are increasingly recognized for their unparalleled reliability and efficiency. This stems from their ability to eliminate the numerous and often redundant AC-to-DC and DC-to-AC conversions that are commonplace in traditional electrical infrastructures.[2]

By simplifying the power path, DC systems inherently reduce potential points of failure and significantly minimize energy losses during transmission and distribution. This direct approach can lead to substantial energy savings, with reported figures indicating a 10-20% reduction in overall energy consumption and a remarkable potential for up to a 40% decrease in grid-sourced power for commercial buildings.[2] Furthermore, DC transmission lines generally exhibit lower losses compared to their AC counterparts, primarily due to the absence of "charging currents" and the "skin effect" that limits current flow to the outer surface of conductors in AC systems.[15]

The seamless integration of DC power with renewable energy sources, such as solar photovoltaic (PV) panels and wind turbines, is another critical factor. These sources inherently generate power in DC form. By utilizing DC systems within buildings, the need for additional AC-DC conversions at the point of generation is eliminated, thereby maximizing the efficiency of energy capture and utilization from these sources.[1] Energy storage systems, predominantly batteries, also operate natively on DC power. Their seamless integration with DC microgrids further reduces overall system costs and significantly enhances reliability, particularly for critical loads and during grid outages.[5]

The vast majority of modern devices and systems that form the backbone of smart buildings—including various sensors, surveillance cameras, advanced LED lighting, and a multitude of Internet of Things (IoT) devices—are fundamentally powered by DC electricity.[3]

The adoption of DC power provides the essential electrical infrastructure for seamlessly integrating these smart technologies, sensors, and IoT devices, thereby significantly boosting overall workplace adaptability and functionality.[2] Innovative fault-managed power solutions leverage DC to enable flexible, zone-based deployment of power and data. This not only accelerates installation times but also reduces new construction and renovation costs for intelligent buildings.[18]

August Berres’s Respond Desks are battery-powered and mobile. USB-C receptacles power modern device designs. An embedded inverter provides AC power at the point of use to enable legacy devices.

This technology also enhances safety by reducing the risk of shock and fire hazards compared to conventional AC wiring.[18] Furthermore, DC power supports enhanced agile workplaces through solutions like August Berres' battery-powered furniture, which eliminates the need for 120V power at every workstation, fostering a more dynamic and responsive environment.[2]

For electrical design firms, embracing DC power is not just about adopting a new technology to offer a wider range of services; it is fundamentally about positioning themselves as leaders and innovators in the design and implementation of next-generation intelligent and sustainable buildings. This strategic imperative means actively developing deep expertise in DC microgrids, understanding fault-managed power solutions, and mastering the seamless integration of diverse renewable energy sources.

Such capabilities are increasingly becoming non-negotiable demands from clients who are focused on reducing their carbon footprint, enhancing operational efficiency, and building resilient infrastructure. This proactive investment in DC expertise therefore becomes a critical strategic differentiator in a competitive and evolving market.

DC power systems deliver consistent and stable voltage levels, effectively eliminating common issues associated with AC power, such as voltage fluctuations, harmonic distortions, and the need for power factor correction. This inherent stability ensures a consistent and reliable power supply, crucial for safeguarding sensitive electronic equipment from potential damage caused by power surges or irregularities. Improved control over voltage regulation and load management within DC systems leads to enhanced overall system performance and protection.[5]

Reduced reliance on the centralized grid, achieved through on-site DC generation and storage, significantly strengthens a building's energy resilience and reduces its vulnerability to external grid disturbances.[2] DC microgrids offer superior reliability, as localized faults are less likely to propagate and cause widespread system failures compared to complex AC systems.[16]

Furthermore, DC equipment, including rectifiers, inverters, and converters, can often be more compact and lightweight than their AC counterparts. This smaller footprint allows for optimized space utilization, which is particularly valuable in space-constrained applications like data centers or telecommunications facilities. The simplified design and reduced component count of DC systems can lead to lower installation and long-term maintenance costs.[5]

Key Advantages and Challenges of DC Power in Building Electrical Systems

A significant barrier to widespread DC adoption is the current lack of broad standardization and acceptance, particularly concerning fundamental aspects like voltage levels, which are well-established for AC technologies.[4]

Organizations like the EMerge Alliance are working to establish standards, focusing on safe, low-voltage DC power distribution (e.g., 24V DC) for interior applications.[21] While the long-term energy cost savings and reduced maintenance can quickly counterbalance upfront expenses, the initial investment required for transitioning to a DC system may appear considerable.[2]

Furthermore, DC technologies are "not generally known or understood by building electrical designers and tradespeople". This lack of familiarity can lead to increased project costs due to steeper learning curves, design inefficiencies, and potential installation errors. There is currently no clear consensus on whether DC power systems are broadly feasible for retrofit applications in existing buildings or if their primary applicability is limited to new construction projects. However, the possibility of converting existing AC branch circuits to DC using existing wiring is being explored.[4]

The transition to DC power involves navigating complex technical and regulatory challenges. Key issues such as safety protocols, comprehensive standardization, and ensuring interoperability across diverse systems remain "open questions" within the industry.[19] While DC offers advantages for very long-distance, high-voltage transmission, at lower voltages, DC can experience significant voltage loss over distance if not properly managed.[15] This necessitates careful design to keep wiring runs relatively short in low-voltage DC applications.[21] Although DC-native devices benefit from direct power, converting between different DC voltage levels or between AC and DC (if a hybrid system is implemented) can still incur "expensive capital costs" and "significant efficiency losses" due to the need for specialized converters and rectifiers.[15]

The research indicates that DC power systems lack the broad standardization and acceptance of AC technologies, and that DC technologies are not generally known or understood by building electrical designers and tradespeople.[4] This dynamic creates a "chicken-and-egg" problem: widespread adoption is significantly hampered by the absence of comprehensive standards and a knowledgeable workforce, yet the development and formalization of these standards and the growth of expertise are inherently slow without broader industry adoption and practical experience.

Electrical firms that demonstrate strategic foresight and proactively invest in developing internal DC expertise, committing to staff training, and undertaking early pilot or demonstration projects (even if these initially involve higher costs or navigate regulatory ambiguities) position themselves as crucial pioneers in this emerging field. Their practical experiences, lessons learned, and contributions to early-stage projects will directly influence the future trajectory of DC standards, the evolution of best practices, and the overall market acceptance of DC power systems. This proactive engagement allows them to shape the industry, gaining a significant first-mover advantage and establishing themselves not merely as service providers but as influential industry shapers.

Integrating DC Component Testing into the Electrical Design Process

Electrical testing and inspections are not merely procedural steps but are fundamental for ensuring system safety, achieving regulatory compliance, and maximizing cost efficiency.[22] They are instrumental in identifying hidden hazards, verifying adherence to evolving regulatory standards, extending the operational lifespan of electrical systems, protecting valuable equipment from damage, and ultimately contributing to significant energy savings.[22] Comprehensive testing involves a thorough examination of the entire electrical system—including wiring, circuit breakers, and other components—to detect potential hazards and confirm compliance with local regulations.

This meticulous process is essential for minimizing critical risks such as electric shock and catastrophic system failures.[22] Compliance testing, in particular, is specifically designed to evaluate and verify the safety of electrical equipment, systems, and installations against established safety standards and regulations. Its primary objective is to identify and mitigate potential electrical hazards, thereby reducing the risk of accidents, fires, and other safety incidents.[23]

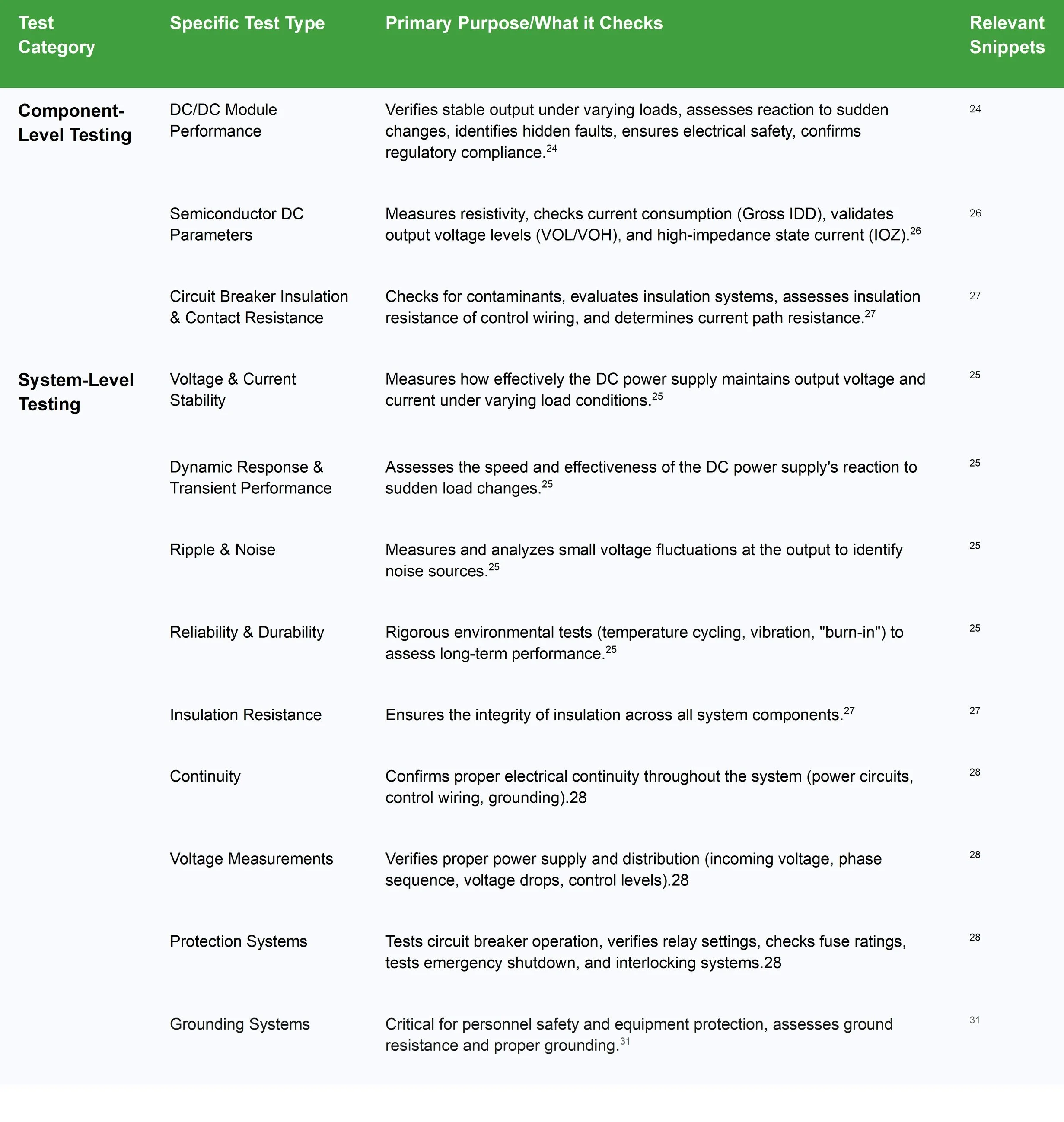

The domain of DC testing encompasses a diverse range of procedures, from micro-level component checks to macro-level integrated system validations. This structured presentation helps electrical engineers and contractors quickly understand the specific tests relevant to DC systems, which may differ significantly from their familiar AC testing protocols. It clarifies why each test is important, linking it directly to ensuring system integrity, performance, and safety. This serves as a valuable practical reference for planning and executing DC projects.

Key DC Component and System Testing Types and Their Purpose

Testing must be viewed not as a post-design formality, but as an integral and iterative part of the design process itself. Leveraging specialized facilities like the DC Systems Experience Center for early-stage validation enables rapid iteration of DC concepts and designs, significantly de-risking novel solutions and preventing costly issues from propagating downstream.[7] For electrical contractors, implementing robust pre-installation and comprehensive commissioning testing becomes a critical quality assurance step. This proactive approach mitigates significant project risks, ensures long-term operational reliability for clients, and directly impacts client satisfaction by minimizing costly callbacks and operational disruptions.

The successful design, installation, and operation of DC power systems in buildings demand not only deep technical expertise in DC principles and applications but also an exceptionally rigorous and well-defined project management and commissioning process. Common commissioning challenges, such as inadequate planning, rushed testing, undefined roles, insufficient documentation, and missing equipment settings [33], are amplified by the inherent technical complexities of DC systems, including their unique fault protection mechanisms, stringent voltage stability requirements, and intricate integration with diverse renewable energy sources.[5]

A minor procedural oversight in an AC system might be manageable, but in a less standardized and more complex DC environment, it could lead to critical failures. Electrical firms must strategically invest in both technical skill development (comprehensive training for their personnel in the specific nuances of DC power systems) and process excellence (establishing and strictly adhering to robust, documented testing and commissioning protocols from the earliest design stages through to post-occupancy). This holistic approach is essential to effectively overcome the inherent complexities and evolving nature of new DC technologies, thereby ensuring safe, compliant, and highly efficient DC installations that meet performance expectations and mitigate long-term operational risks.

The placement of testing within the project lifecycle is crucial for optimal outcomes. During the design and prototyping phases, facilities like the DC Systems Experience Center provide a crucial "live lab for testing and prototype development in a real environment" [7], enabling early validation of DC concepts and designs. This allows for iterative refinement before significant investment. During early design phases, critical electrical properties are defined, topology is selected, and PCB layouts are developed, all of which inform and are impacted by initial testing parameters.[35]

For pre-installation and acceptance testing, a series of essential tests are conducted prior to system energization. These include detailed visual inspections, insulation resistance tests, continuity tests, and precise voltage measurements.[28] Contractor field tests, such as medium-voltage cable testing, load balancing, phase rotation checks, and infrared (IR) scanning of terminations and connections, are common specification requirements to ensure proper installation and identify potential issues.32 Partial discharge (PD) testing, often using very low-frequency voltage, can be applied to new, old, and live cables to detect insulation weaknesses before they lead to failures.[32] The ANSI/NETA ATS-2017 standard is a widely recommended benchmark for acceptance testing specifications for electrical power equipment and systems, ensuring initial operational integrity.[32]

Commissioning is a systematic and documented quality control and assurance process designed to verify that a facility's systems fully meet the functional and performance requirements of the building owner, occupants, and operators.[36] It critically ensures that systems are installed correctly and will operate precisely as designed, encompassing individual component testing, meticulous verification of interconnections against drawings, and comprehensive functional testing of the system as a whole.[37]

Key steps include a thorough review of the system and equipment, development of a detailed test plan, conducting inspections and checks, performing component-level testing, verifying wiring continuity, checking control functions, calibrating instruments and relays, and sequentially energizing circuits.37 Integrated Systems Testing (IST), sometimes referred to as "pull-the-plug" tests, is particularly critical for mission-critical facilities like data centers. These tests confirm that the entire system, including multiple power paths, generators, and uninterruptible power supplies, functions as intended under simulated power loss scenarios.[32]

Finally, ongoing maintenance and monitoring are indispensable for safety, compliance, and efficiency. Regular inspections and periodic testing (e.g., Residual Current Devices (RCDs) every three months) are essential for maintaining safety, ensuring continuous compliance, mitigating risks, sustaining reliability, and optimizing efficiency throughout the system's operational life.[23]

Post-occupancy reviews are crucial to assess system performance after the building is operational, gather occupant feedback, and make necessary adjustments, ensuring systems continue to meet performance expectations over time.[33] Infrared (IR) scanning is a valuable diagnostic tool used both during new installation start-ups and as part of ongoing maintenance programs to detect excess heat in electrical systems, which can indicate unbalanced loads, loose connections, or other issues.[32] The ANSI NETA MTS 2015 is a recognized standard for maintenance testing specifications for electrical power equipment and systems, providing a framework for ongoing preventive maintenance.[32]

Relevant Standards and Regulations for DC Electrical Systems in Buildings

The regulatory framework for electrical installations, particularly concerning DC power, is a critical consideration for all electrical professionals. NFPA 70, widely known as the National Electrical Code (NEC), serves as the foundational benchmark for safe electrical design, installation, and inspection practices across the United States. Its provisions are legally enforced in all 50 states, ensuring protection for people and property from electrical hazards.[38]

Specifically, NEC Article 690.31(D) provides detailed regulations for Direct-Current Circuits installed on or within buildings. Its primary focus, as indicated in the provided information, is on Photovoltaic (PV) system DC circuits.[20] For PV system DC circuits that exceed 30 volts or 8 amperes when installed inside buildings, the NEC mandates that they must be enclosed within metal raceways, utilize Type MC metal-clad cable (provided it complies with NEC Section 250.118(10)), or be housed in metal enclosures.[20]

Rigorous marking and labeling requirements are stipulated for PV system DC circuits. These include permanently affixed labels bearing the wording "WARNING: PHOTOVOLTAULC POWER SOURCE," which must be clearly visible after installation. The labels require capitalized letters with a minimum height of 3/8 inch in white on a red background, and spacing between labels or markings must not exceed 3 meters (10 feet).[20]

General requirements for wiring methods and materials applicable to all electrical installations, including DC, are found in NEC Chapter 3, specifically Article 300. This article serves as a comprehensive "catchall" for wiring methods not explicitly detailed in other specific articles within Chapter 3.[40] Low-voltage wiring is generally defined as systems operating at 50 volts or less, with common commercial applications utilizing standard voltages of 12V, 24V, or 48V.[39]

The NEC (NFPA 70) is the universally accepted standard for safe low voltage installations across the United States.[39] NEC Article 242 addresses overvoltage protection, outlining general and installation requirements for Surge-Protective Devices (SPDs) and surge arresters for both low-voltage and high-voltage systems.[41] Article 250 establishes the comprehensive performance and prescriptive requirements for grounding and bonding electrical systems, crucial for safety and equipment protection.[41]

Beyond national codes, international and industry-specific standards also play a vital role. The IEC (International Electrotechnical Commission) publishes a broad spectrum of standards relevant to electrical installations. This includes the IEC 60364 series, which covers fundamental principles, protection for safety, and selection/erection of equipment for low-voltage electrical installations, as well as IEC 60146-1-1 for semiconductor converters.[42]

The IEEE (Institute of Electrical and Electronics Engineers) develops specialized standards pertinent to DC microgrids. For instance, IEEE 2030.10-2021 specifically addresses the architecture of DC microgrids designed for rural and remote applications, typically with a nominal distribution voltage of 48V. This standard primarily focuses on the power distribution aspect of a microgrid and how various sources connect to it.[43]

NECA (National Electrical Contractors Association) provides ANSI-approved performance and workmanship industry standards (NEIS) that are widely used in electrical construction and frequently referenced within the National Electrical Code itself.45 NECA also publishes standards for commissioning building electrical systems (e.g., NECA90-15PDF) and for the installation and maintenance of Electric Vehicle Supply Equipment (EVSE) (e.g., NECA413-19).[45]

The existing regulatory and standards framework is lagging behind the accelerating technological advancements and growing market demand for broader DC applications in buildings. The NEC, while comprehensive for AC, primarily addresses DC in the specific context of PV systems.[20]

Concurrently, there is a "lack of broad standardization and acceptance" for general DC power systems, and standardization and interoperability are "open questions".[4] This presents a dual challenge for electrical professionals: uncertainty in design and installation due to incomplete guidelines, and the potential for non-standardized installations that might require costly future modifications.

However, it also creates a significant opportunity. Firms that proactively engage with emerging standards bodies (such as contributing to or closely following IEEE 2030.10 for microgrids [43]) or collaborate with industry initiatives (like the EMerge Alliance [21]) can actively influence the future direction and content of DC standards. This strategic engagement positions them as thought leaders and ensures their designs and installations are aligned with future compliance requirements, potentially granting them a crucial first-mover advantage in a rapidly growing, albeit currently less regulated, market segment.

While the focus is on DC, several sources consistently emphasize the concept of "hybrid AC/DC installations" or "hybrid buildings" as the practical and likely near-term future.[2] It is explicitly stated that "a move to 100 percent DC buildings is difficult to imagine, hybrid buildings with both AC and DC components may be possible".[4]

Furthermore, initiatives like EMerge Alliance are "not trying to replace a building's AC wiring" but rather creating a "DC power distribution layer" that coexists with existing AC infrastructure.21 This indicates that the immediate future of building electrical systems is not a wholesale replacement of AC with DC, but rather a sophisticated integration of DC elements into existing AC frameworks.

Electrical engineers and designers must therefore develop expertise not just in isolated pure DC systems, but, more critically, in the nuanced design, seamless integration, and efficient operation of hybrid AC/DC systems. This requires a deep understanding of the complex interactions between AC and DC components, proficiency in managing energy conversions efficiently, and a strong focus on ensuring robust interoperability between disparate systems. The strategic emphasis shifts from an "either/or" paradigm to a "how to best combine and optimize" approach. This broader, integrated skillset will be a key differentiator in the market, enabling professionals to deliver truly future-proof and highly efficient building electrical solutions.

The Role of Energy Service Companies (ESCOs) in the DC Transition

Energy Service Companies (ESCOs) are pivotal players in the broader energy transition, offering a comprehensive suite of solutions that can significantly accelerate the adoption of DC power in buildings. An ESCO is defined as a company that provides a broad range of energy solutions, including the design and implementation of energy savings projects, retrofitting, energy conservation, energy infrastructure outsourcing, power generation, energy supply, and risk management.[46] Unlike traditional energy companies that primarily supply energy, ESCOs differentiate themselves by offering comprehensive services aimed at improving energy efficiency.[46]

ESCOs typically engage with clients through performance-based contracts, often referred to as Energy Savings Performance Contracts (ESPCs).[46] Under this model, the ESCO identifies, designs, installs, and commissions energy conservation measures, and critically, guarantees the energy savings.[47] If the project does not deliver the promised savings, the ESCO is responsible for covering the difference, thereby mitigating financial risk for the client.[46] This unique approach makes ESCOs distinct from consulting engineers or equipment contractors, as they assume project risk and are paid based on verified energy savings.[46]

Their role in the DC transition is multifaceted:

Project Development and Integration: ESCOs act as project developers, integrating the design, financing, installation, and operational elements of energy efficiency retrofits.[47] This comprehensive approach is particularly beneficial for complex DC projects that involve integrating various technologies like solar PV, battery storage, and smart building systems.

De-risking Investment: By guaranteeing energy savings, ESCOs reduce the financial uncertainty associated with adopting new technologies like DC power systems. This can encourage building owners and operators to invest in DC solutions, even if the initial capital outlay appears significant.[46]

Expertise and Implementation: ESCOs possess extensive design and implementation experience in integrating multiple efficiency measures and mitigating technical and performance risks.47 They can provide specialized expertise that may not be available in-house, covering everything from energy audits and engineering designs to project management, equipment procurement, installation, and ongoing maintenance.[46]

Financing Mechanisms: ESCOs often arrange project financing, allowing clients to fund energy efficiency upgrades, including DC system installations, entirely from the realized future energy savings, without requiring upfront capital.[46] This innovative financing mechanism can be a significant enabler for organizations looking to transition to DC power.

Alignment with Sustainability Goals: ESCOs' work directly contributes to reducing energy consumption and carbon footprints, aligning with broader sustainability and decarbonization efforts.[48] For instance, the DC Department of General Services partnered with an ESCO to implement an ESPC aimed at cutting energy waste and improving public facility conditions, leveraging guaranteed savings to fund upgrades like new HVAC and lighting systems.[48]

In essence, ESCOs serve as strategic partners that can bridge the gap between the potential benefits of DC power and the practical challenges of its implementation, offering integrated solutions that ensure long-term success and financial viability for clients.

Conclusion and Recommendations

The analysis presented underscores a pivotal moment in the electrical industry, characterized by the accelerating adoption of DC power in building systems. Specialized facilities like the DC Systems Experience Center are invaluable resources for electrical engineers, contractors, and designers. They provide critical platforms for de-risking novel DC concepts, fostering industry-wide innovation, and accelerating market adoption through practical, live lab testing and collaborative knowledge exchange.[1]

The landscape of outsourcing in low-voltage and general electrical work is currently prevalent, often driven by the need for flexible capacity and access to specialized external expertise.8 However, there is an emerging and growing trend towards insourcing for core competencies, particularly in the nascent field of DC power. This shift is motivated by a desire for enhanced quality control, greater protection of intellectual property, and improved direct communication, alongside the broader industry challenge of a talent gap.[12]

DC power is rapidly becoming an indispensable component for future-proof building designs. It offers substantial advantages in energy efficiency, enables seamless integration with renewable energy sources, and is fundamental to the functionality of smart building technologies and IoT devices, including fault-managed power solutions and agile battery-powered furniture.[2] These benefits are compelling despite existing challenges related to standardization, initial investment costs, and the current knowledge gaps within the workforce.[4]

Comprehensive DC component and system testing is not a singular event but an iterative and continuous process. It is vital to integrate testing methodologies from the earliest design phases through pre-installation, acceptance, and rigorous commissioning.[7] This continuous validation is crucial for ensuring the safety, compliance, and optimal performance of complex DC installations, mitigating risks throughout the project lifecycle. The regulatory environment for DC power is still evolving. Current electrical codes primarily address DC in specific applications, such as photovoltaic systems, highlighting a clear need for proactive engagement with emerging standards and industry initiatives to support broader DC adoption and ensure future compliance.[4]

Based on these findings, the following actionable recommendations are provided for electrical engineers, contractors, and designers:

Leveraging Experience Centers for Innovation: Electrical professionals should actively seek out and engage with specialized facilities, such as the DC Systems Experience Center. These visits offer invaluable hands-on experience with emerging DC technologies, allowing for the validation of new design concepts in a controlled environment and fostering critical networking opportunities with industry innovators and researchers.[7] Strategically leveraging these "live lab" environments for prototyping and rigorously testing specific DC applications that align with current or prospective project pipelines can significantly reduce on-site risks, accelerate project deployment timelines, and enhance confidence in new DC solutions.

Strategic Insourcing/Outsourcing Decisions for DC Work: A thorough and nuanced analysis of core versus non-core business activities specifically related to DC power is recommended. Given the strategic importance of DC, firms should consider a deliberate strategy of insourcing DC design and highly specialized engineering functions. This approach helps build internal expertise, ensures greater control over intellectual property, and enhances overall quality control, which is particularly critical in an industry facing a talent gap.[12] For non-core or more routine DC installation tasks, strategically utilizing outsourcing can manage capacity peaks and access specialized labor. However, it is imperative to establish robust communication protocols, clear performance metrics, and explicit liability agreements with external partners to mitigate potential risks.

Prioritizing DC Power Expertise and Adoption: A significant and continuous investment in training and upskilling existing staff in fundamental DC power principles, advanced design methodologies, best installation practices, and effective maintenance procedures is crucial. This proactive approach directly addresses the current knowledge gap in the industry and strategically positions the firm for sustained growth in the evolving energy landscape.[4] Firms should proactively integrate DC power solutions into new building designs and retrofit projects, starting with well-established applications like EV charging infrastructure, LED lighting systems, and integrated smart building technologies, including fault-managed power and agile battery-powered furniture.

This allows for the accumulation of practical experience, demonstrates technical leadership, and builds a strong portfolio in the DC domain. Active engagement with relevant industry bodies, standards organizations (e.g., IEEE, EMerge Alliance), and regulatory authorities is also advised to stay informed about evolving DC standards and contribute to their development. This foresight ensures designs are future-compatible and helps shape the regulatory environment.[19]

Implementing Robust DC Testing and Commissioning Protocols: Embedding comprehensive DC testing methodologies from the earliest design phases of a project is essential, utilizing advanced simulation tools and physical prototyping facilities to validate concepts and identify potential issues proactively.[7] Firms must develop detailed pre-installation, acceptance, and commissioning plans specifically tailored for DC systems. These plans should address the unique challenges inherent in DC installations, such as specialized fault protection schemes, complex grounding requirements, and stringent power quality considerations.[27]

Prioritizing integrated systems testing (IST) is critical to ensure the seamless and reliable operation of hybrid AC/DC environments and the effective interaction of interconnected smart building technologies. This holistic testing approach is crucial for verifying system-wide performance under various conditions.[28] Finally, establishing robust ongoing maintenance and monitoring programs for all DC installations, including regular checks and data analysis, is vital to ensure long-term reliability, maintain optimal efficiency, and preemptively address any potential issues, thereby maximizing the lifespan and performance of the DC systems.[23]

Collaborating with Energy Service Companies (ESCOs): Electrical professionals should explore partnerships with ESCOs to leverage their expertise in designing, financing, and implementing comprehensive energy efficiency projects. ESCOs' performance-based contracts can de-risk the adoption of DC power systems for clients, providing a pathway for integrating advanced DC solutions, including fault-managed power and battery-powered furniture, into new constructions and retrofits without significant upfront capital investment. This collaboration can accelerate market penetration for DC technologies and contribute to broader energy transition goals.[46]

The global DC Distribution Network market is poised for substantial growth, with projections indicating an increase from USD 17.29 Billion in 2023 to USD 29.49 Billion by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 7.57%.[51] This trajectory underscores that DC power is not merely a niche application but a foundational element of future energy systems in the built environment. Electrical professionals who proactively embrace this transition, invest in specialized knowledge, and refine their operational processes will be best positioned to lead and innovate in this evolving landscape.

Works cited

First 'Direct Current Experience Center' opened in the Netherlands ..., accessed May 28, 2025, https://energycentral.com/news/first-direct-current-experience-center-opened-netherlands

DC Power: A Holistic Approach to Energy Savings in Commercial Buildings - Realcomm, accessed May 28, 2025, https://www.realcomm.com/news/1192/2/dc-power-a-holistic-approach-to-energy-savings-in-commercial-buildings

cencepower.com, accessed May 28, 2025, https://cencepower.com/blog-posts/5-reasons-dc-electricity-should-replace-ac-electricity-in-buildings#:~:text=2.-,Essential%20for%20Smart%20Buildings%20to%20Work%20Efficiently,all%20powered%20with%20DC%20electricity.

DC Power in Buildings: Separating the Hype from Reality - Cooperative.com, accessed May 28, 2025, https://www.cooperative.com/programs-services/bts/Documents/TechSurveillance/DCPowerinBuildings.pdf

4 Advantages of DC Power Systems for Industrial Applications, accessed May 28, 2025, https://www.anscorporate.com/blog/dc-power-systems-for-industrial-applications

Direct Current (DC) Buildings and Smart Grid - Department of Energy, accessed May 28, 2025, https://www.energy.gov/eere/buildings/articles/direct-current-dc-buildings-and-smart-grid

Benefits of hybrid AC/DC installations - Schneider Electric Blog, accessed May 28, 2025, https://blog.se.com/innovation/2025/04/29/the-benefits-of-hybrid-ac-dc-installations-an-inside-look-at-dc-systems-experience-center/

Domestic outsourcing is on the rise. What happens when the practice is banned? | Federal Reserve Bank of Minneapolis, accessed May 28, 2025, https://www.minneapolisfed.org/article/2024/domestic-outsourcing-is-on-the-rise-what-happens-when-the-practice-is-banned

Outsource.net: Electrical and Low-Voltage Staffing Nationwide, accessed May 28, 2025, https://outsource.net/

What It Takes to Be a Low-Voltage Contractor - Outsource.net, accessed May 28, 2025, https://outsource.net/what-it-takes-to-be-a-low-voltage-contractor/

Outsourcing and Accidents in the Electrical Sector - ResearchGate, accessed May 28, 2025, https://www.researchgate.net/publication/306013482_Outsourcing_and_Accidents_in_the_Electrical_Sector

Insourcing vs. Outsourcing in electrical engineering design | WSCAD-BLOG, accessed May 28, 2025, https://blog.wscad.com/en/outsourcing-in-electrical-engineering-design/

Insourcing vs. Outsourcing Consulting Services - DZConneX, accessed May 28, 2025, https://www.dzconnex.com/blog/insourcing-vs.-outsourcing-consulting-services

Navigating 4 key trends and challenges shaping the power industry | Utility Dive, accessed May 28, 2025, https://www.utilitydive.com/news/trends-challenges-utility-power-industry-workforce-doble/747199/

What challenges are associated with long-distance transmission of DC power, and how do high-voltage DC (HVDC) cables address these challenges? - Quora, accessed May 28, 2025, https://www.quora.com/What-challenges-are-associated-with-long-distance-transmission-of-DC-power-and-how-do-high-voltage-DC-HVDC-cables-address-these-challenges

DC Microgrid Deployments and Challenges: A Comprehensive Review of Academic and Corporate Implementations - MDPI, accessed May 28, 2025, https://www.mdpi.com/1996-1073/18/5/1064

From Efficiency to Safety: How Low Voltage Solutions Are Shaping the Future, accessed May 28, 2025, https://www.core-states.com/corenews/from-efficiency-to-safety-how-low-voltage-solutions-are-shaping-the-future/

Intelligent Buildings - VoltServer Digital Electricity, accessed May 28, 2025, https://voltserver.com/intelligent-buildings/

Is it time to rethink our grid? Why industry should take a serious look at DC Power - ISPT, accessed May 28, 2025, https://ispt.eu/conference/news/is-it-time-to-rethink-our-grid-why-industry-should-take-a-serious-look-at-dc-power/

690.31(D) Direct-Current Circuits on or in Buildings. - Electrical License Renewal, accessed May 28, 2025, https://www.electricallicenserenewal.com/Electrical-Continuing-Education-Courses/NEC-Content.php?sectionID=965

Occupied Space Standard FAQs - EMerge Alliance, accessed May 28, 2025, https://www.emergealliance.org/standards/occupied-space-2/standard-faqs/

Benefits of Professional Electrical Inspections & Testing - Mario Castillo Electric, accessed May 28, 2025, https://mariocastilloelectric.com/blog/benefits-of-professional-electrical-inspections-and-testing-with-mario-castillo-electric/

Understanding the Importance of Electrical Safety Compliance and Testing - Ronika, accessed May 28, 2025, https://www.ronika.net.au/understanding-the-importance-of-electrical-safety-compliance-and-testing

Test Methods for DC/DC Power Modules, accessed May 28, 2025, https://flexpowermodules.com/resources/fpm-designnote027-test-methods

Key Technical Requirements for DC Power Testing - INFINIPOWER, accessed May 28, 2025, https://www.infinipowertech.com/technical-requirements-for-dc-power-supply-testing/

Semiconductor Testing Fundamentals - DC Parameter Testing - Power's Wiki, accessed May 28, 2025, https://wiki-power.com/en/%E5%8D%8A%E5%AF%BC%E4%BD%93%E6%B5%8B%E8%AF%95%E5%9F%BA%E7%A1%80-DC%E5%8F%82%E6%95%B0%E6%B5%8B%E8%AF%95/

DC Testing and Maintenance- What You Need To Know - POWER PLUS Engineering, Inc., accessed May 28, 2025, https://www.epowerplus.com/blog/dc-testing-and-maintenance--what-you-need-to-know_ae14.html

Electrical commissioning procedure in substation, accessed May 28, 2025, https://substationfaults.com/electrical-commissioning-procedure/

Protection Relay Testing and Commissioning - CED Engineering, accessed May 28, 2025, https://www.cedengineering.com/userfiles/Protection%20Relay%20Testing%20and%20Commissioning-R1.pdf

1 UNITED STATES OF AMERICA BEFORE THE FEDERAL ENERGY REGULATORY COMMISSION Protection System Maintenance ) Reliability Standard - NERC, accessed May 28, 2025, https://www.nerc.com/FilingsOrders/us/NERC%20Filings%20to%20FERC%20DL/Commissioning%20Testing%20of%20Protection%20Systems%20Info%20Filing.pdf

Grounding Testing and Maintenance - Monolithic Power Systems, accessed May 28, 2025, https://www.monolithicpower.com/en/learning/mpscholar/ac-power/grounding-practices/grounding-testing-and-maintenance

Considerations for electrical testing and commissioning - Consulting ..., accessed May 28, 2025, https://www.csemag.com/considerations-for-electrical-testing-and-commissioning/

Common Commissioning Challenges and How to Overcome Them, accessed May 28, 2025, https://sanconltd.com/2025/03/19/common-mistakes-commissioning/

Commissioning best practices: Electrical — Top 10 deficiencies and challenges - Consulting, accessed May 28, 2025, https://www.csemag.com/commissioning-best-practices-electrical-top-10-deficiencies-and-challenges/

AC/DC Power Supply Design in 7 Steps | FSP TECHNOLOGY INC., accessed May 28, 2025, https://www.fsp-group.com/en/knowledge-tec-23.html

Commissioning - DEDC, accessed May 28, 2025, https://www.dedc-eng.com/wp-content/uploads/2017/10/DEDC-Booklet-COMMISSIONING-2017.pdf

COMMISSIONING MAJOR ELECTRICAL SYSTEMS - PDH Online, accessed May 28, 2025, https://pdhonline.com/courses/e409/e409content.pdf

NFPA 70 (NEC) Code Development, accessed May 28, 2025, https://www.nfpa.org/codes-and-standards/nfpa-70-standard-development/70

Low Voltage Wiring Code: All You Need To Know - The Network Installers, accessed May 28, 2025, https://thenetworkinstallers.com/blog/low-voltage-wiring-code/

General Requirements for Wiring Methods in the NEC - NFPA, accessed May 28, 2025, https://www.nfpa.org/news-blogs-and-articles/blogs/2025/02/03/overview-of-nec-article-300

NEC Code 101: Your Expert Guide to Electrical Installations - Ledes, accessed May 28, 2025, https://www.ledestube.com/nec-code-101-your-expert-guide-to-electrical-installations/

Electrical regulations and standards, accessed May 28, 2025, https://www.electrical-installation.org/enwiki/Electrical_regulations_and_standards

IEEE 2030.10-2021 - Accuris Standards Store, accessed May 28, 2025, https://store.accuristech.com/ieee/products/vendor_id/10742

Ieee Standard For DC Microgrids For Rural and Remote Electricity Access Applications, accessed May 28, 2025, https://www.scribd.com/document/786351297/203010-2021

The Standards | NECA - National Electrical Contractors Association, accessed May 28, 2025, https://www.necanet.org/topics/codesandstandards/neis/the-standards

Energy service company - Wikipedia, accessed May 28, 2025, https://en.wikipedia.org/wiki/Energy_service_company

The ESCO Story - National Association of Energy Service Companies | NAESCO, accessed May 28, 2025, https://www.naesco.org/esco/

The Department of General Services Announces DC's First Energy Savings Performance Contract in Honor of Earth Day - DC DGS, accessed May 28, 2025, https://dgs.dc.gov/vi/node/1777606

Working Sector-by-Sector - Commission on Climate Change and Resiliency, accessed May 28, 2025, https://climatecommission.dc.gov/sites/default/files/dc/sites/climatecommission/WorkingSectorbySector_Combined.pdf

5 Critical Power Supply Challenges in Industrial Automation - Bel Fuse, accessed May 28, 2025, https://www.belfuse.com/resource-library/blog/five-critical-power-supply-challenges-in-industrial-automation

DC Distribution Network Market Analysis & Forecasts, 2020-2024 & 2025-2030 with Analyst Recommendations - Adopt Sustainable Practices / Optimize Supply Chain and Manufacturing - ResearchAndMarkets.com, accessed May 28, 2025, https://www.businesswire.com/news/home/20250205868071/en/DC-Distribution-Network-Market-Analysis-Forecasts-2020-2024-2025-2030-with-Analyst-Recommendations---Adopt-Sustainable-Practices-Optimize-Supply-Chain-and-Manufacturing---ResearchAndMarkets.com